Description

Function:

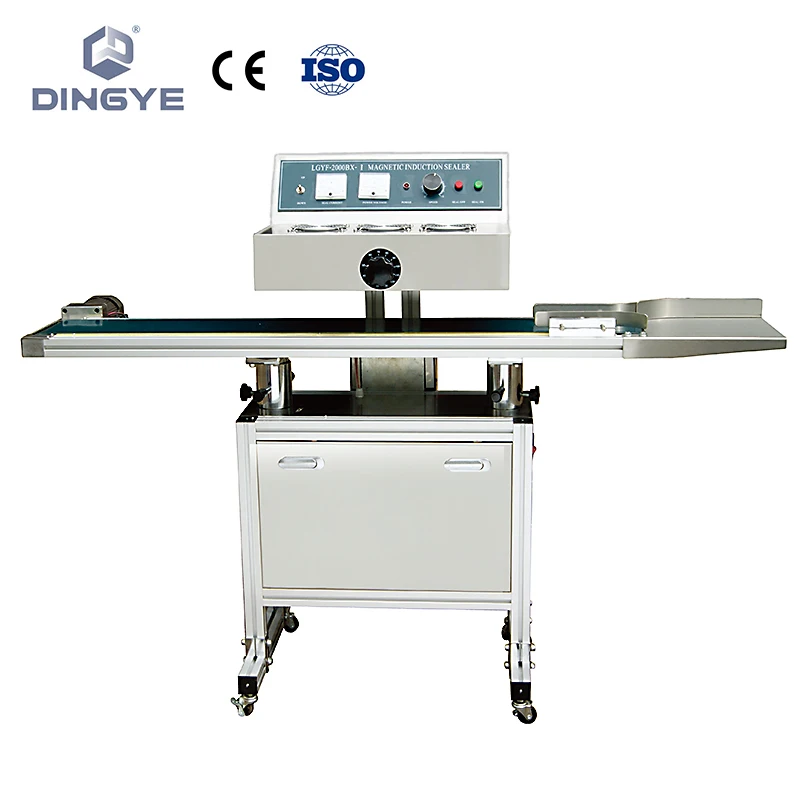

1.LGYF-2000BX continuous induction sealer adheres to the bung hole, reaching the aim of wet-proof, leakage-proof, mildew-proof and extending preservation time.

2.It is widely used as sealing package machine in industries such as pharmaceuticals, pesticides,pesticides, lubricant and cosmetics etc.

3.Aluminum foil is sealed automatically when bottle is transmitted through under induction coil by conveyor.

|

Model

|

LGYF-2000BX

|

|

voltage

|

220V 50/60HZ

|

|

Power

|

1.5KW

|

|

Capacity

|

0-12m/min

|

|

Sealing Diameter

|

20-130mm

|

|

Suitable Height of bottles

|

40-400mm

|

|

Machine weight

|

72kg

|

|

Machine size

|

1550*550*1350mm

|