Description

Main Features

1.This machine is 2 in 1 shrink packager newly developed by our company, which achieves sealing, cutting and shrinking on the same machine. It has exquisite design, easy to operate.

2.The film frame can be up and down adjusted. And the conveyor guide can be folded. It has compact structure, small volume, which is convenient for transport.

3.It has separated components for Seal-cut and shrinking function, which also can be used alone. The work efficiency is much highly improved than FM5540 2 IN 1 shrink packager.

4.Low power consumption, which is suitable to apply in family.

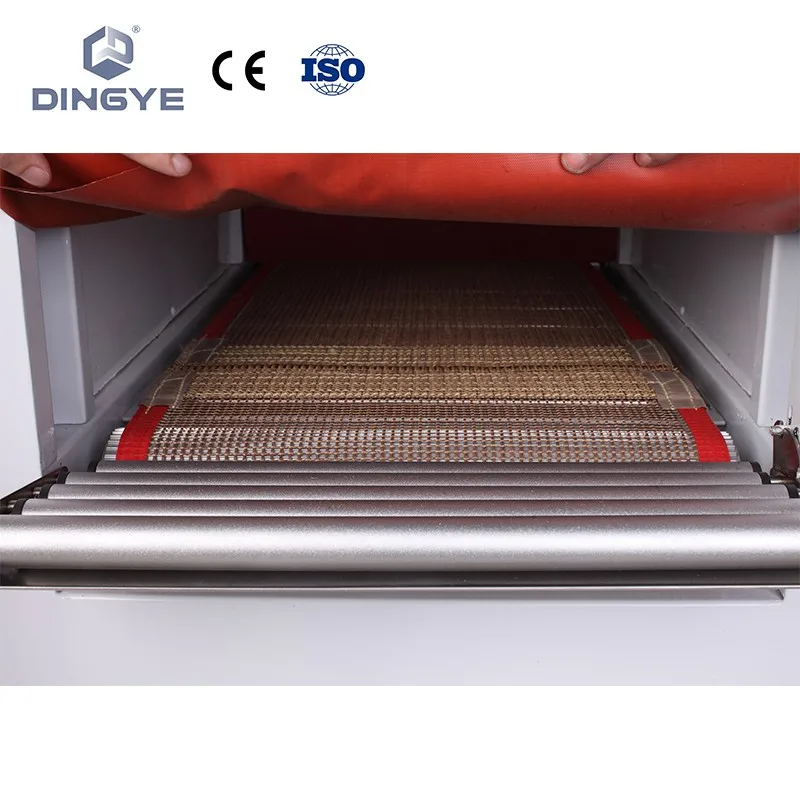

5.The shrinking chamber adopts inner heating cycle, which ensures even heating so as to achieve excellent and perfect shrinkage.