Efficient Capping Machines: Automated Bottle Capping Solutions

Product Categories

Technical Specifications of our Capping Machines

Automatic Filling And Capping Machine (production Line)

Additional information

Semi-automatic Capper

Additional information

Automatic Capping Machine For Bottle (suitable For Aluminum Ropp Cap)

Additional information

Bottle Cap Machine Jgs-880 Multi-purpose Locking And Capping Machine

Additional information

Multi-purpose Locking And Capping Machine Jgs-980 Glass Bottle Cap Locking Machine

Additional information

Automatic Capping Machine For Bottle (suitable For Plastic Screw Cap)

Additional information

Automatic Capping Machine For Bottle (suitable For Plastic Sport Cap)

Additional information

Key Features & Benefits

- High automation levels, reducing manual labor.

- Fast capping speeds to meet high-volume production needs.

- Compatible with various bottle types and caps.

- Easy to operate and maintain with user-friendly controls.

- Built with safety features to ensure safe operation.

- Energy-efficient design to minimize operational costs.

Applications & Use Cases

Food and Beverage

Sealing bottles for drinks, sauces, and condiments.

Pharmaceuticals

Ensuring tamper-proof sealing for medication bottles.

Cosmetics

Sealing cosmetic packaging such as lotions and serums.

Why Choose Us

Technical Highlights: Precision and Innovation

Equipped with high-precision sensors and automation software, our machines deliver unmatched accuracy and efficiency.

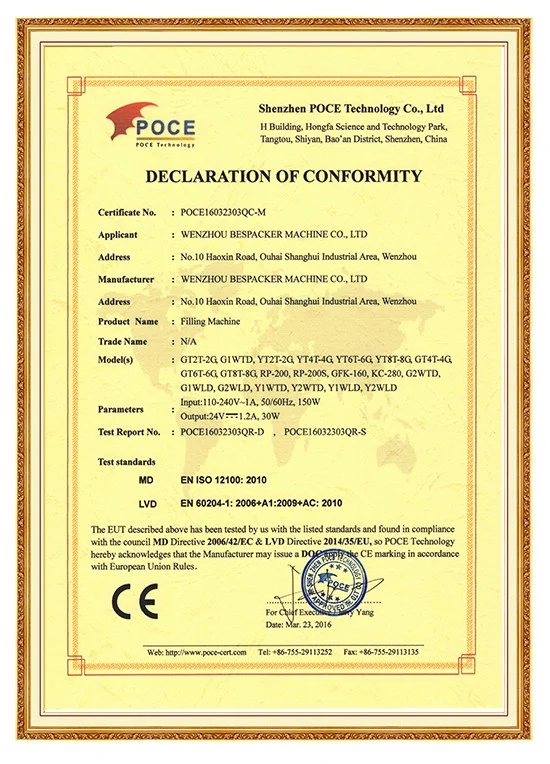

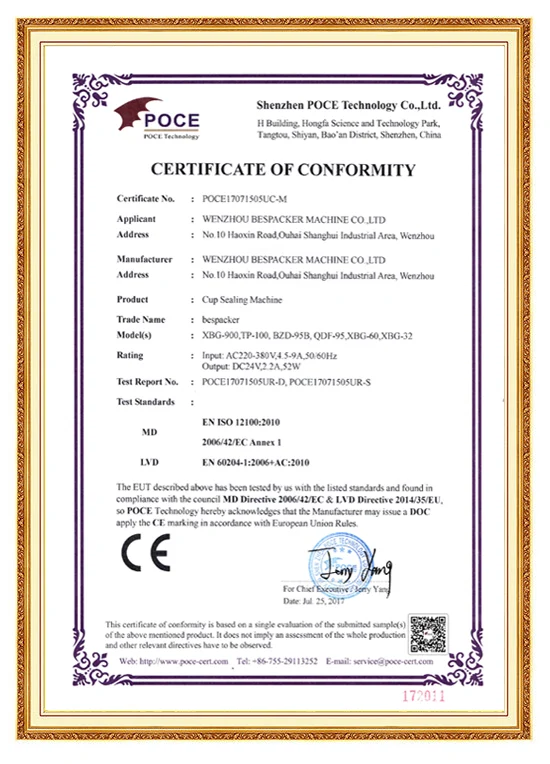

Certified Excellence

All our machines meet stringent quality and safety standards, backed by ISO 9001 certification and CE marking, ensuring compliance with global industry requirements and customer trust.

After-Sales Support

We provide comprehensive support, including installation, training, and maintenance. Our dedicated team ensures your machinery operates smoothly, reducing downtime and maximizing productivity.

Customers Reviews

Our capping machines are trusted by leading companies worldwide. Here’s what our customers say:

“The capping machine has significantly improved our production efficiency. It’s reliable and easy to use. Highly recommend!

— John Doe, Beverage Manufacturer

Frequently Asked Questions

Qualification certificate

CE, ISO 9001

Request a Free Quote

Interested in your packaging machine? Contact us today and let’s build the perfect filling solution for your business!