Precision Filling Solutions for Every Viscosity

Whether you are packaging free-flowing water or high-viscosity cosmetic creams, choosing the right filling equipment is crucial for efficiency and accuracy. ALF PACK provides a comprehensive range of filling machinery engineered to meet diverse industrial needs:

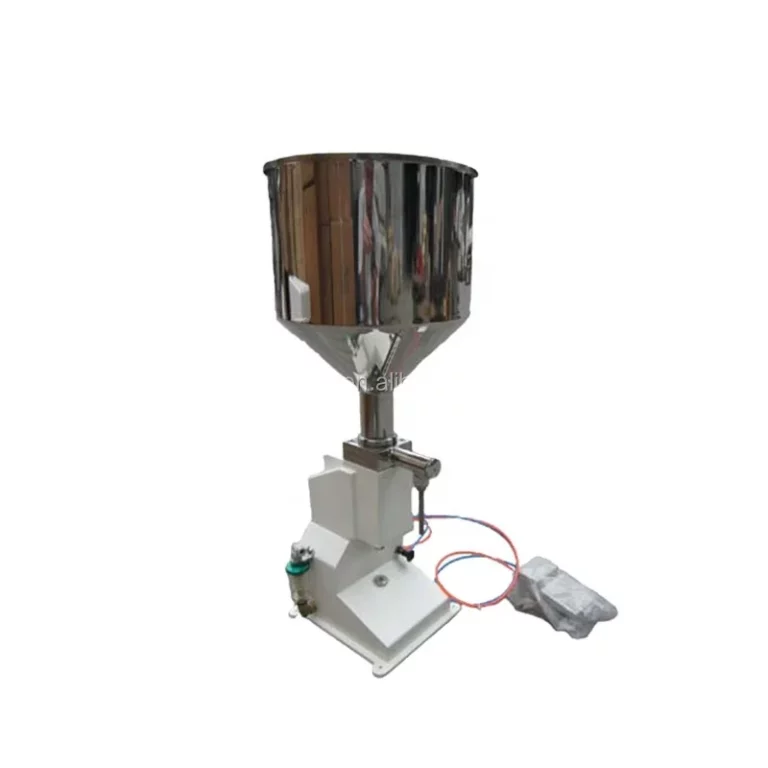

Manual & Pneumatic Fillers: Ideal for startups and small-batch production (e.g., A02, A03 series), offering cost-effective precision for pastes and liquids.

Automatic Filling Lines: Designed for high-volume production (e.g., AS2000 series), featuring PLC controls, photocell sensors, and seamless integration with capping and labeling systems.

Industry Compliance: All machines are built with food-grade stainless steel, ensuring compliance with hygiene standards for food, beverage, and pharmaceutical sectors.

Product Categories

Explore Our Filling Machines

A02 Pneumatic Filler (pedal)

Additional information

A03 Manual Fruit Juice Filling Machine

Additional information

Automatic Liquid Filling And Packing Machine

Additional information

Automatic Liquid Packaging Machine (filling And Sealing)

Additional information

As2000p Automatic Liquid Packer With Photocell

Additional information

As2000s Automatic Double Tube Liquid Packager

Additional information

Automatic Complete 5 Gallon Bottle Filling Machine

Additional information

Bg32a Automatic Cup Filling And Sealing Machine (for Two Cups) For Soil Bean Milk Fruit Juice Mineral Water

Additional information

Bg48s Automatic Milk Bottles Filling And Sealing Machine

Additional information

Bg60a Automatic Plastic Cup Filling Sealing Machine (for Four Cups)

Additional information

Bg60p Automatic Plastic Cup Filling And Sealing Machine (for Four Cups) For Sticky Liquid And Paste Material Filling

Additional information

Cfd Series Fully Automatic Cup Filling And Sealing Machine (for Four Cups) Pneumatic Type For Big Capacity

Additional information

Custom Filling Solutions for Every Industry

Food and Beverage

filling of liquids, sauces, carbonated beverages, etc.

Pharmaceuticals

precision filling, ensure no pollution.

Chemical industry

corrosion-resistant materials, safe filling

Why Choose Our Filling Machines?

Technical Highlights: Precision and Innovation

Equipped with high-precision sensors and automation software, our machines deliver unmatched accuracy and efficiency.

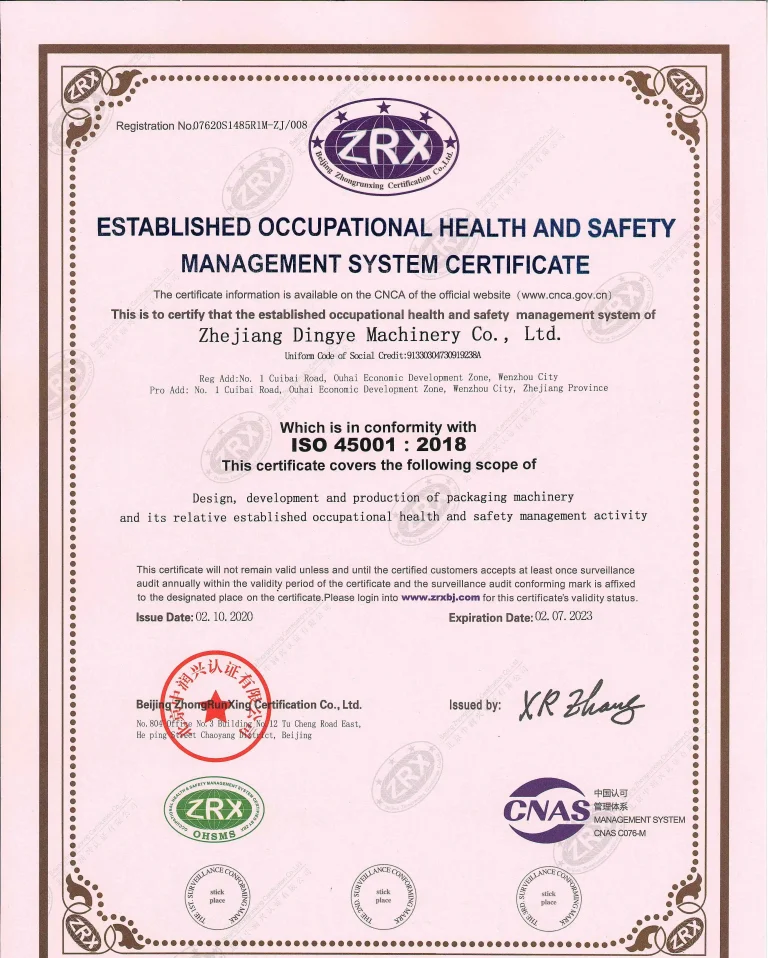

Certified Excellence

All our machines meet stringent quality and safety standards, backed by ISO 9001 certification and CE marking, ensuring compliance with global industry requirements and customer trust.

After-Sales Support

We provide comprehensive support, including installation, training, and maintenance. Our dedicated team ensures your machinery operates smoothly, reducing downtime and maximizing productivity.

Customer Cases and Scenarios

Automatic Red Wine Filling Line

Deployed for a winery client. This AS-Series automated line achieves 2,000 bottles/hour with zero-drip nozzles, ensuring precise liquid level control for premium glass bottles.

Round Bottle Labeling Application

Seamless integration. The labeling module applies wrap-around labels with ±1mm accuracy, crucial for maintaining brand image on retail shelves.

Success Stories

Good Quality! Highly recommended!

Project: 5-Gallon Water Line for Middle East Market

Challenge: The client needed to switch from manual filling to a fully automated system to meet increasing summer demand.

Solution: We installed the QGF-100 Automatic Washing, Filling, and Capping Machine.

Result: “Production capacity increased by 200%. ALF PACK’s engineer provided on-site installation and training within 3 days.”

Frequently Asked Questions

A filling machine is a device that automatically or semi-automatically fills containers with a specified amount of product, such as liquids, powders, or granules. It dispenses the product into the container, ensuring accuracy and efficiency.

Several types of filling machines are available, including liquid filling machines, powder filling machines, capsule filling machines, and both semi-automatic and fully automatic models. Each type is designed for specific products and production speeds.

Consider factors such as the type of product you fill (liquid, powder, capsules), production volume, required speed, and any industry-specific regulations. Also, assess the ease of maintenance and durability of the machine.

This is tutorial for you!

Industries such as food and beverage, pharmaceuticals, cosmetics, chemicals, and agriculture use filling machines. Each industry requires specialized machines for different types of products.

The choice depends on your production volume and material viscosity.

A02 (Pneumatic): Requires an air compressor. It is less tiring for the operator and better for continuous, higher-volume batches. It handles thicker pastes (like peanut butter) more effectively.

A03 (Manual): Requires no electricity or air source. It is perfect for labs, small shops, or areas with no power supply. Best for medium-viscosity liquids and creams.

Certifications & Quality Assurance

At ALF PACK, every filling machine is built to meet CE and ISO 9001 standards. These certifications confirm that our machines comply with strict requirements for safety, accuracy, and reliability. CE certification ensures conformity with European safety and performance regulations, while ISO 9001 guarantees consistent manufacturing processes and quality control. Together, they demonstrate our commitment to high-precision engineering, stable performance, and customer satisfaction in every filling solution.