L Bar Sealers & Shrink Wrap Heat Sealers

Industrial Grade Packaging Solutions for Efficiency and Reliability

Product Categories

Enhance Packaging Efficiency with Professional L Sealers

Featured L Bar Sealers & Shrink Systems

- Space-saving design

- Visual shrink wrapping process

- Combined seal and shrink tunnel function

- Easy-load film dispenser

A versatile unit where the bar shrink action and heat chamber are combined. Perfect for small workshops requiring high quality finishes in limited space.

Additional information

Semi-automatic L-bar Sealer

Additional information

Semi-automatic L-bar Sealer

Additional information

- Semi automatic l bar operation

- Heavy duty frame construction

- Consistent pneumatic pressure

- Large seal size: 550x450mm

Ideal for mid-volume lines. Unlike manual models that rely solely on magnetic hold, this pneumatic unit uses air cylinders to ensure a perfect seal area compression every cycle.

Additional information

Pneumatic L-type Sealer And Shrink Tunnel

Additional information

Pneumatic L Type Sealer For Plastic Film

Additional information

Continuous Seal-cut- Shrink Packaging Machine

Additional information

Automatic Side Sealer And Shrink Tunnel

Additional information

High Speed Side Sealer

Additional information

High Speed Automatic L Sealer

Additional information

High Speed Automatic L Sealer And Shrink Tunnel

Additional information

Long Items Packaging Machine

Additional information

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Choosing the Right Machine: Manual vs. Automatic

| Feature | Manual L Sealer | Pneumatic L Sealer | Automatic L Sealer |

|---|---|---|---|

| Operator Effort | High (Manual Press) | Low (Push Button) | None (Conveyor Fed) |

| Speed (PPM) | 4 – 8 | 10 – 15 | 25 – 60+ |

| Consistency | Variable | High | Perfect |

| Best Application | Low volume / Irregular shapes | Mid volume / Multipacks | High volume / Uniform boxes |

Technical Excellence in Every Detail

Choosing the right shrink wrap machines involves more than just speed; it requires looking at the components that ensure longevity and performance.

Sealing Technology: The Hot Knife Advantage

For our automatic l bar sealer series, we utilize a premium hot knife sealing system. Unlike standard wire sealers, the hot knife is a single piece of alloy coated with Teflon. This ensures a durable heat seal that won’t break during high-speed runs. The knife maintains a constant temperature, creating a fine, strong seal line that virtually disappears after passing through the shrink tunnel.

Film Handling & Preparation

Proper film management is crucial for efficient shrink wrapping. Our machines are equipped with:

- Film Dispenser: A smooth-rolling carriage that supports heavy rolls of shrink film, ensuring even tension.

- Film Separator: A mechanical device that opens the center-folded film before the product enters, preventing jams in the seal area.

- Perforated Hole Punchers: Integrated pin-wheels that prick tiny holes in the film. This allows air to escape during the shrinking process, preventing “ballooning” and ensuring the film conforms tightly to the product.

Heavy Duty Construction for Industrial Use

Whether you choose a semi automatic l sealer or a fully automated line, durability is standard. Our machines feature heavy duty steel frames designed to minimize vibration. For manual and semi-auto units, features like magnetic hold (electromagnets that hold the arm down during the seal cycle) reduce operator fatigue, allowing for consistent throughput shift after shift.

Customers Reviews

Our l sealers are trusted by companies worldwide. Here’s what our customers say:

We use the ALFPack L Bar Sealer on our beverage multipack line, and it has been extremely reliable.

The sealing is clean and consistent, even during long production runs, and the machine integrates well with our shrink tunnel.

It helped us improve packaging efficiency and reduce rework caused by poor seals.

Overall, it’s a solid solution for beverage companies looking for stable, professional shrink packaging.

Why Choose Our L Bar Heat Sealer?

An L bar sealer gets its name from the shape of the sealing jaw, which forms a right angle (L-shape). This design allows the machine to seal the trailing edge of the previous package and the leading edge of the new package simultaneously, while also sealing the side. This efficiency makes it superior to straight I-bar sealers for any business doing more than a few packages per hour.

Key Technologies in Our Shrink Wrap Heat Sealers

- Anti-Adhesive Coating: Our sealing knives are coated with high-grade Teflon or alloy materials to prevent molten plastic from sticking to the blade, ensuring a clean cut every time and reducing smoke.

- Digital Temperature Control: Precise PID controllers maintain the heating element temperature within a tight range. This is crucial for shrink wrap heat sealers because temperature fluctuations can cause weak seals (which open in the tunnel) or burnt film.

- Safety Systems: All our pneumatic and automatic L sealers come equipped with safety sensors. If an object (like a hand or a misplaced product) is detected under the seal bar, the machine automatically reverses direction to prevent injury or damage.

20+ Years Experience

Industry-leading vacuum technology.

1-Year Global Warranty

Free parts replacement for pump & motor issues within 12 months.

Custom Solutions

After-Sales Support

Maintenance Tips

Proper maintenance helps an L bar sealer run safely and produce clean, strong seals.

Daily

Clean the sealing blade to remove film residue.

Check the PTFE (Teflon) tape and replace it if damaged.

Make sure the film feeds smoothly.

Test the emergency stop and safety cover.

Weekly

Inspect the sealing blade or wire for wear.

Check sealing temperature settings.

Tighten loose screws and bolts.

Clean sensors and photo eyes.

Monthly

Lubricate moving parts (avoid the sealing area).

Check electrical and pneumatic connections.

Run test packs to confirm seal quality.

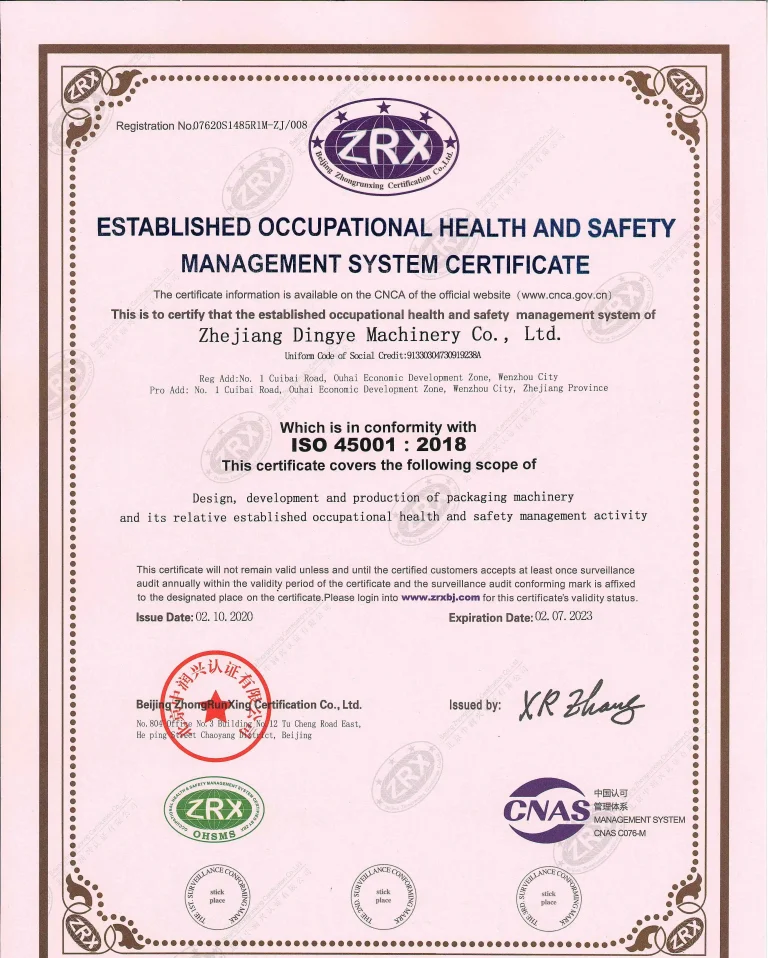

International Compliance & Certifications

At ALF PACK, every carton sealer is built to meet CE and ISO 9001 standards. These certifications prove that our machines follow strict safety, quality, and reliability requirements. CE ensures compliance with European safety and performance regulations, while ISO 9001 guarantees consistent manufacturing and quality control. Together, they reflect our commitment to high-quality engineering and customer satisfaction in every packaging solution.

About us

We are a professional manufacturer specializing in L bar sealer production lines. Our manufacturing process covers precision machining, assembly, testing, and strict quality control to ensure stable performance and long service life. Supported by experienced engineers and standardized production procedures, our L bar sealers deliver reliable and consistent sealing results for food, beverage, pharmaceutical, and industrial packaging applications. We also offer OEM and ODM services to meet the specific needs of different markets and customers.

Request a Quote

Ready to Work Together? Build a project with us!

Frequently Asked Questions

A hot knife is a solid sealing bar that provides a much stronger and more consistent heat seal than a thin wire. It requires less maintenance and is standard on our high quality automatic machines.

Perforated hole punchers are essential for allowing air to escape from the package inside the shrink tunnel. Without them, trapped air would cause the shrink film to bubble or burst.

We offer standalone sealers, but for a complete shrink wrapping solution, we recommend pairing our semi automatic l bar units with a compatible shrink tunnel to achieve a professional finish.

You should choose a machine with a seal area that is at least 2-3 inches larger than your largest product’s dimensions (Length + Height, and Width + Height) to allow room for the film to seal comfortably around the item.