Description

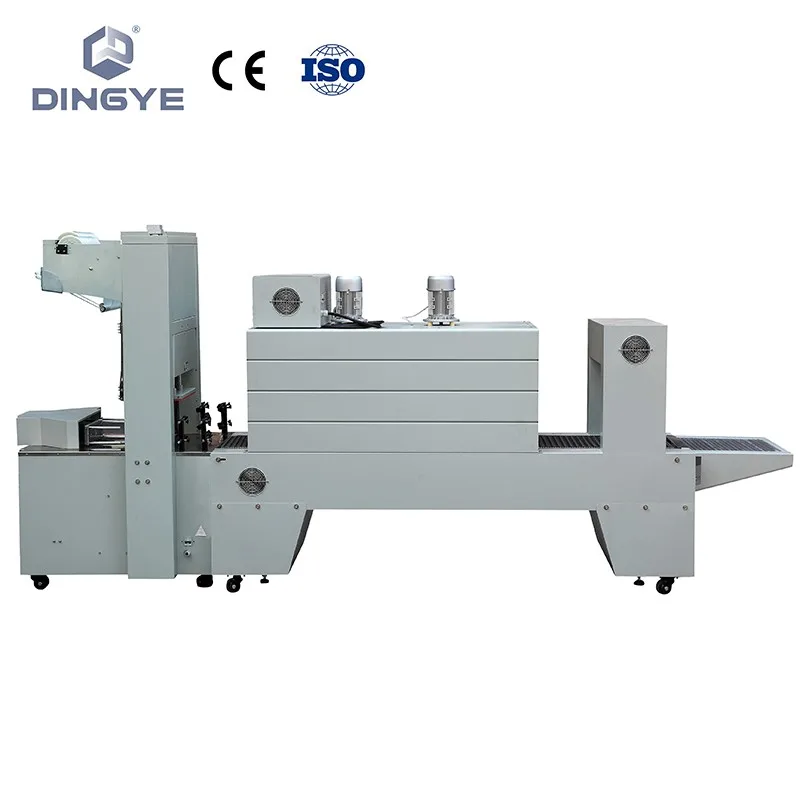

BZJ5038 series sleeve wrapper is suitable for wrapping pop-cans, bottles, etc, with bottom-tray or without bottom-tray, working with BSE-5038 or other PE shrink tunnels.

The machine adopts the Germany advanced technology and international famous brands, which makes capability stable and using long-time. Enlarge packing range or custom-made machine according to customer’s requirement.

Characteristic:

1. Upper and down electromagnetic switch prevent sealing mistakes, and protect operator.

2. Every simply and easy to adjust machine to match different packing size.

3. Simple operation and maintenance with high packing efficiency.

4. ‘Schneider’ AC contractor, and Intelligent temperature controller performs stable.

5. Automatic alarm security system protects machine and operator.

6. Large power conveyer motor, with stepless speed regulating, ensures smooth feeding.

7. Two large power fans make the temperature of shrink tunnel every even and stable, this ensures the excellent effect of shrinking in one time.

8. Super cooling system cools the packing and makes the figuration perfectly.