Description

1. Adopt special electonic controlling circuit for heating, high efficiency in simultaneous controlling one lamp or more, lower power consumption

2. Adopt the theory of heat transfer and feedback while designing the shap and thickness of preform

3. The preform will be heated evenly, not be influenced by outside enviroment

4. Cooling system with cold air cycle ensures same heat exposure of internal and external surface of the bottles

5. The air exhaust system designed by CAD can guarantee the deviation of heating furance temperature ±1 degree

6. Air circuit system consists of movement and blowing so as to meet the needs of different air pressure, also to provide stable high pressure for blowing different shapes of big capacity bottles

7. The system is equiped with silencer, connecting rod and articulated refueling devices

8. Two modes of operation: semi-automatic mode and automatic mode

9. Small size, low investment. One person enough to operate, simple and safe

Specification:

|

Model |

DYS-2-1500 |

|

Theoretical output |

800B/H |

|

Max volume |

2.0L |

|

Max height |

360mm |

|

Max diameter |

105mm |

|

Number of cavities |

2 |

|

Mould plate dimension |

L:490mm*H405mm |

|

Mould thickness |

220mm |

|

Mould opening stroke |

180mm |

|

Power |

220-380V/50-60HZ |

|

Total power |

11kw |

|

Heating power |

10kw |

|

Main body dimension |

L:1500*W650*H2000mm |

|

Main body weight |

550kg |

|

Pre-heater dimension |

L:1400*W650*H1500mm |

|

Pre-heater weight |

300kg |

0.1-2.5L(2 cavity) 3-6L(1 cavity)

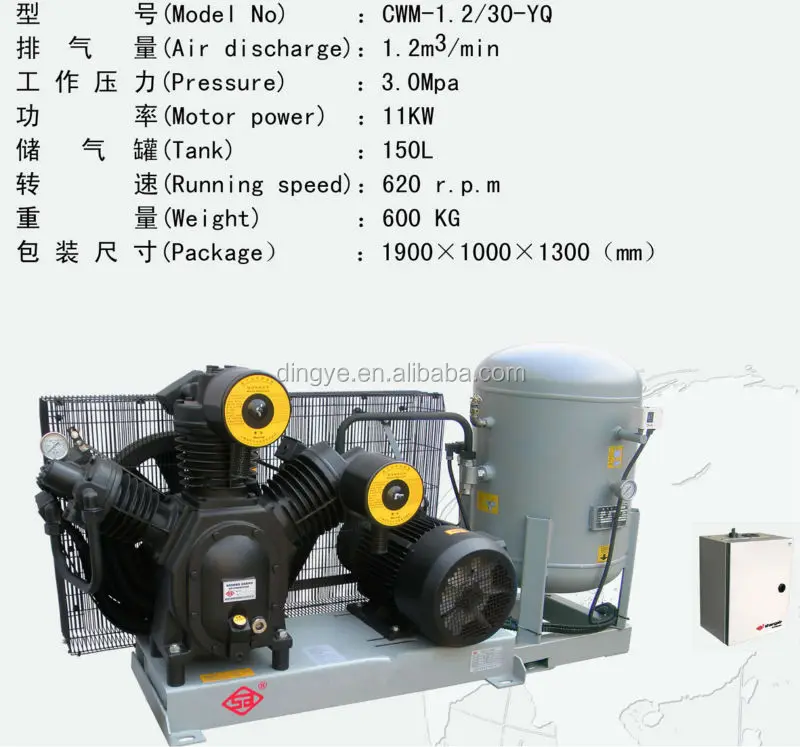

air compressor

FAL-1.0/30 air filter

|

Model |

FAL-1.030 |

|

Free air delivery |

1.0m³/min |

|

Air pressure |

3.0Mpa |

|

Overall dimension |

650*250*350 |

|

Weight |

10kg |